A 6.5 MGD linerboard facility located in the Mid-Atlantic United States faced an ongoing issue with odors emanating from a primary clarifier and equalization basins upstream of its activated sludge system. Increasing complaints from the community prompted the mill to take action to bring the odors under control.

Because different odors can be generated biologically under varying conditions, identifying the specific compounds involved and their sources is essential for effective troubleshooting. Water and air samples were collected from the nearest upstream lift station, the primary clarifier, and the equalization basins, and were analyzed for various potential odor-causing compounds.

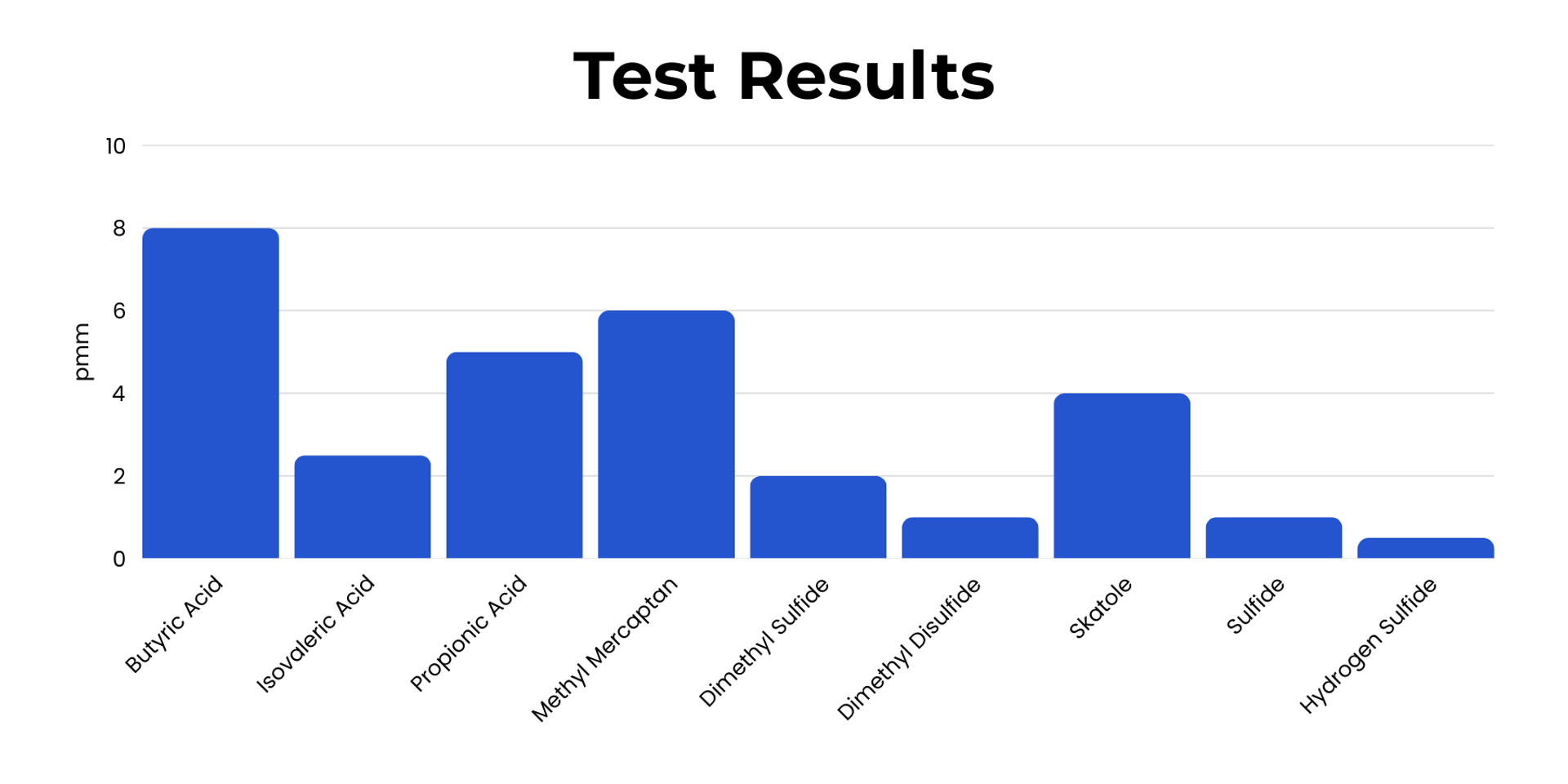

Volatile organic acids were identified as the primary contributors to the odor issue. Methyl mercaptan and other reduced sulfur compounds were also detected at elevated concentrations in the primary clarifier and equalization basins. Oxidation-reduction potential (ORP) readings and pH levels indicated an environment conducive to the growth of nuisance bacteria that produce these compounds under anaerobic conditions.

A combined treatment was recommended: OdorCap 5700, which oxidizes existing odors and helps prevent the formation of new ones, along with a nitrate source to discourage the growth of odor-producing bacteria.

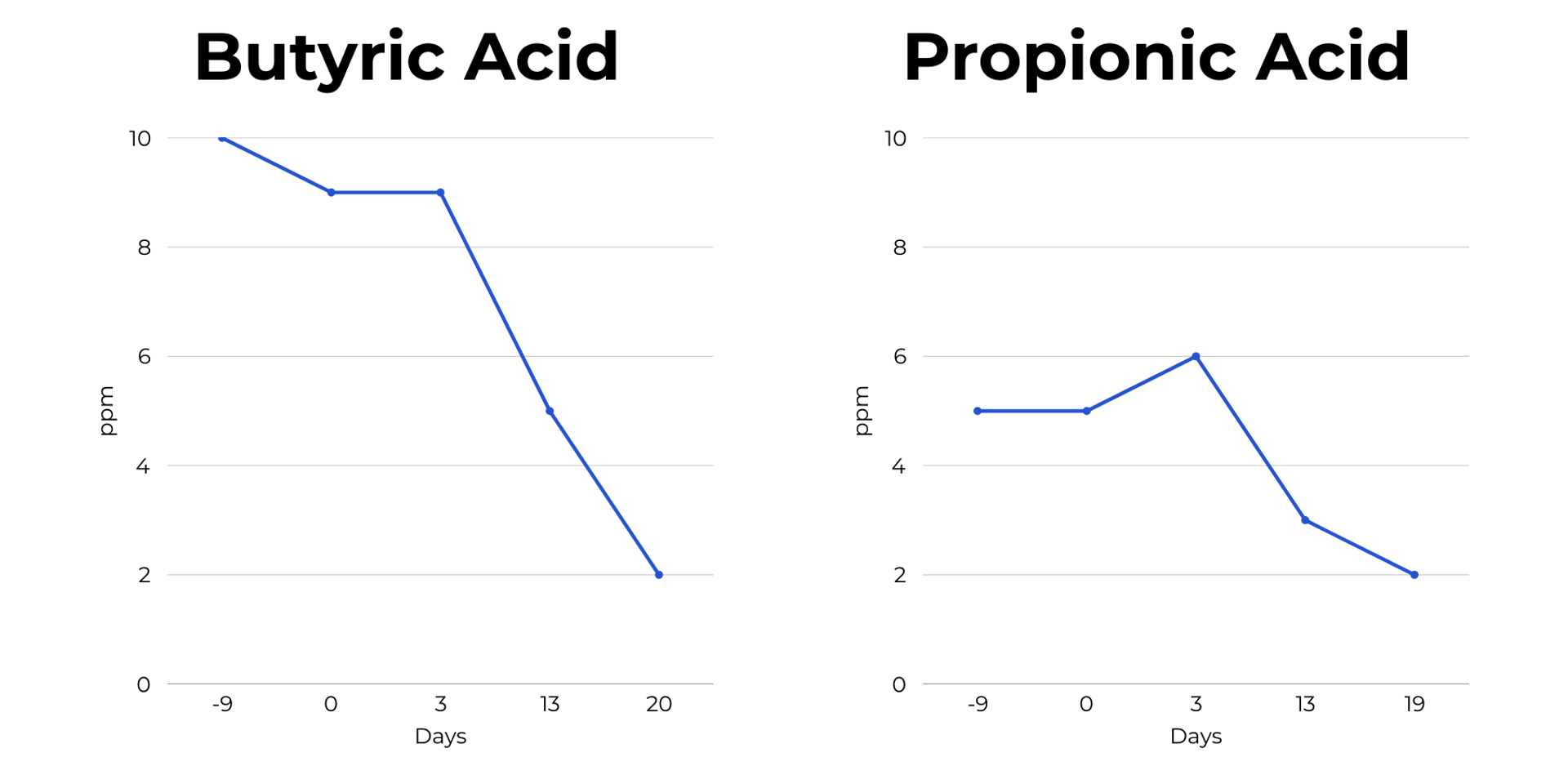

Within days, plant personnel observed that the odors had virtually disappeared, and community complaints had ceased. Air and water sample data collected before and during the use of OdorCap 5700 verified the effectiveness of the odor control strategy.