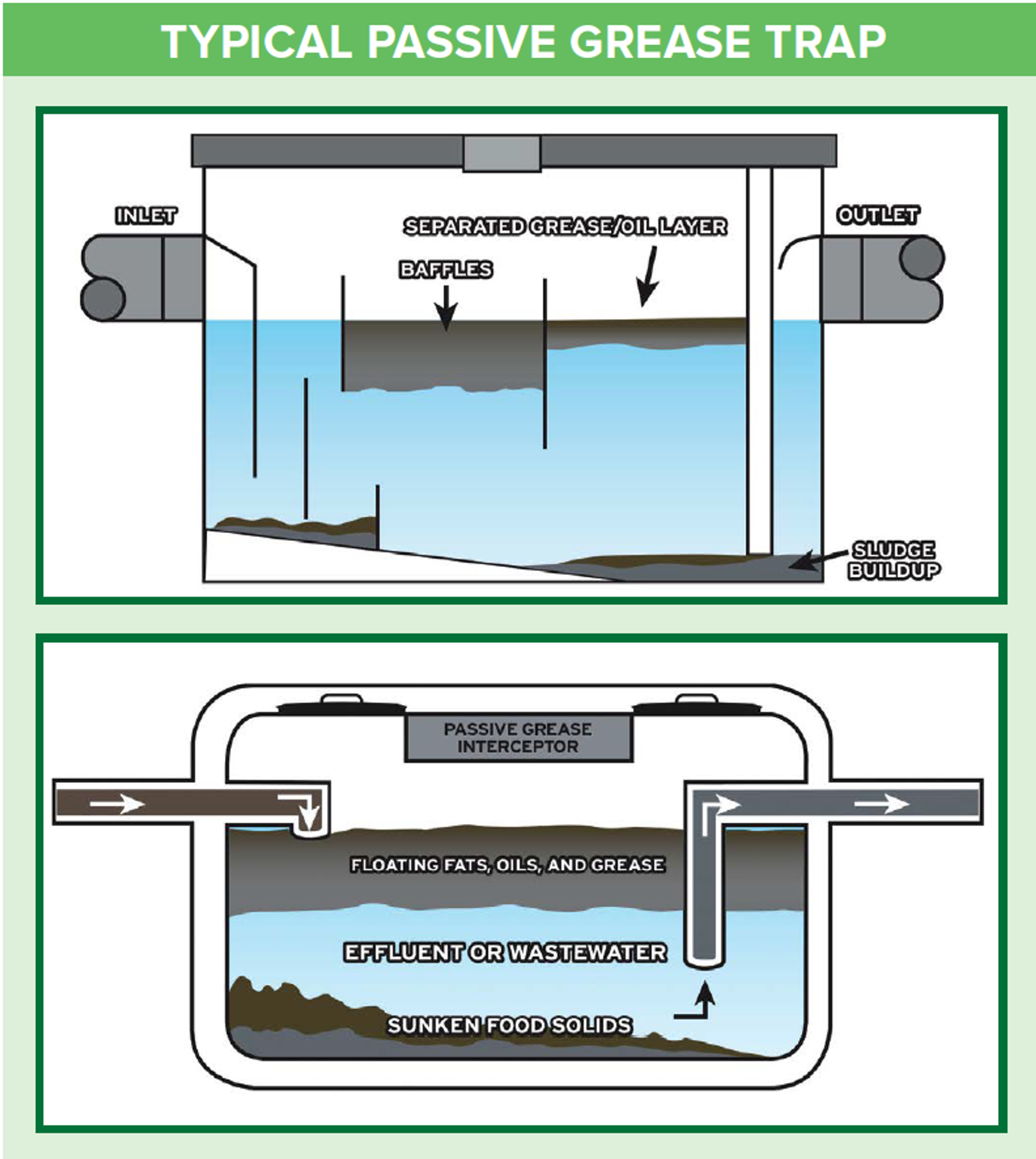

A grease trap is a plumbing device designed to intercept most greases and solids before they enter a wastewater disposal system. The traps reduce the amount of fats, oils, and greases (FOGs) that enter sewers.

The grease trap tank acts as a reservoir holding the wastewater and food solids that enter the trap. As the wastewater cools, the fat, oil, and grease (FOG) harden and the food solids settle. The FOG, being lighter than water, floats to the top of the grease trap.

Jar #1 contains tap water and corn oil. An oil soluble dye has been added to the contents. The contents were shaken up and allowed to rest for 24 hours before this picture was taken.

Jar #2, a surfactant-based product was added to the same preparation of water, corn oil and blue dye. The jar was shaken and again allowed to sit undisturbed for 24 hours. The surfactant combined with the oil to form an emulsion that allows the corn oil to be uniformly dispersed in the water.

Jar #3 was prepared by mixing two milliliters of the emulsified corn oil with 500 ml of tap water and allowed to sit for 24 hours. This simulates the dilution of emulsified FOG with water in the municipal collection system. The additional water dilutes the surfactant to the point that it no longer emulsifies the corn oil, the emulsion breaks, and the oil separates from the water. This separation of the oil in the collection system causes all kinds of problems for the municipality, and so treatment of grease traps with surfactants is understandably regulated.

EnviroZyme offers solid, powder and liquid solutions that release billions of beneficial bacteria into the treatment area to digest FOG and maintain clean, free-flowing systems, while also reducing malodors at their source. Each of these products saves money by reducing the frequency of manual clean-outs, preventing blockages, and lowering grease disposal costs.

Solids dissolve gradually, allowing for continuous treatment over many weeks.