Dissolution Rates: Why Not All Solids Are Created Equal

How Do Solid Delivery Systems Work?

Solids are designed to provide continuous biological treatment by dissolving over a length of time, anywhere from 24 hours up to 90 days. This type of delivery system offers many pros:

• Longer service times

• Delivers chemical without a pump or labor needed

• Can deliver bacteria in conjunction with other water treatment chemicals

• In pond and lagoon applications, sinks to bottom to treat sludge in direct proximity

• Long shelf life

Dissolution rates, however, must be consistent in order for a solid product to steadily deliver bacteria and provide maximum effectiveness.

What Factors Affect Dissolution Rate?

Chemistry

Each solid contains bacteria and a wealth of other components. Bacterial strains are selected based on a product’s intended substrate and have nothing to do with dissolution rate.

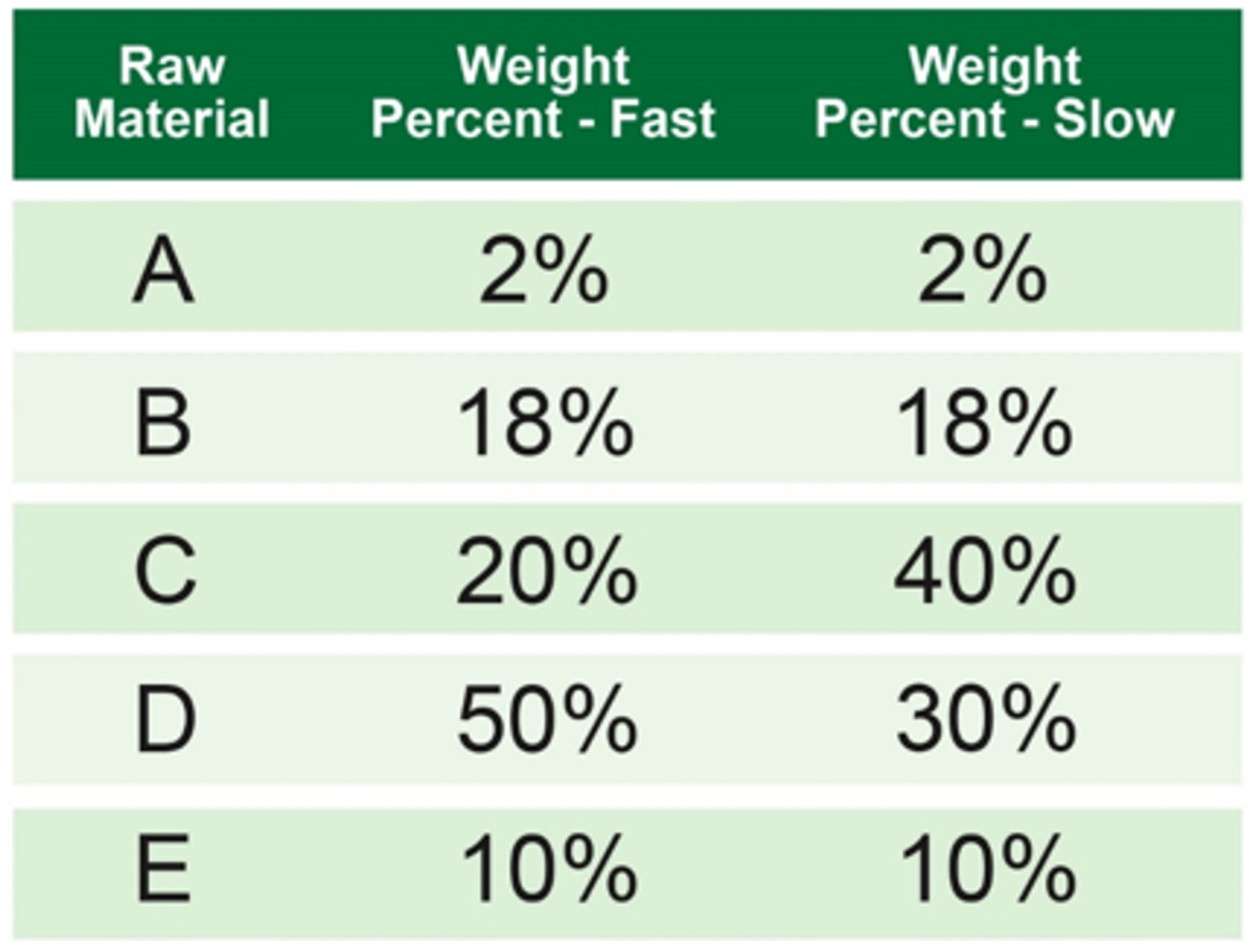

Dissolution rate is determined, in part, by the other raw material components, some of which dissolve rapidly, others of which dissolve more slowly. Ratio between these families of compounds is manipulated to achieve different dissolution rates, as shown in the cart on the right.

By adjusting the chemistry of the block, the dissolution rate can be tuned for 24 hours, up to 90 days. Each specific length of time has value, depending on the application.

Size and Aspect Ratio

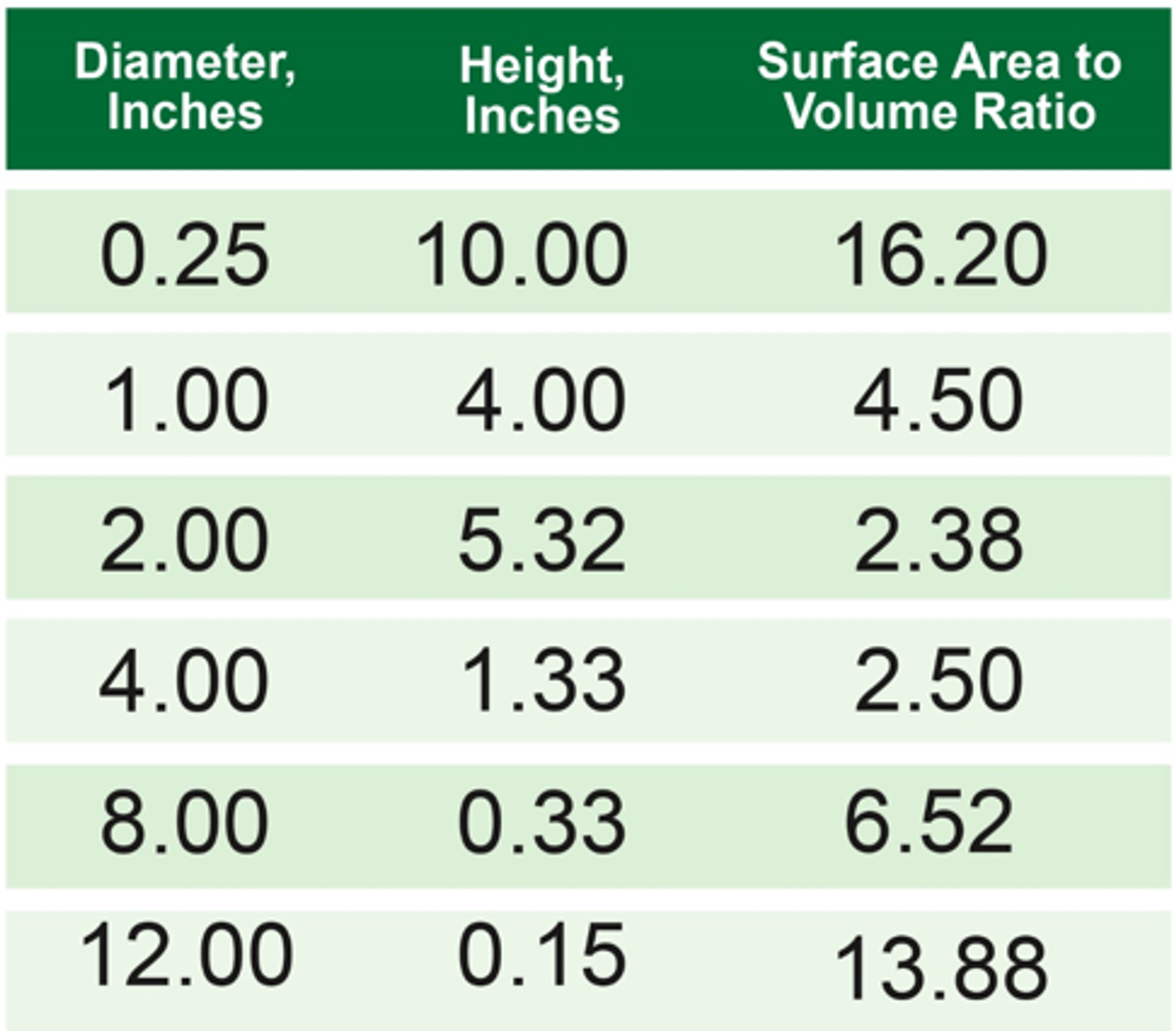

Extruded solids can take many shapes. The diameter and height of each solid’s shape informs the surface area to volume ratio, which is very important with regard to dissolution rate. As extreme examples, a block of soap shaped like spaghetti or a piece of paper will dissolve more rapidly than one shaped like a baseball. This concept is quantified by the ratio of surface area to volume.

Size is fairly intuitive—a bigger block with identical chemistry and surface area to volume ratio will last longer than a smaller block. Institutional solids range from 16 grams to 16 ounces, and municipal and industrial solids generally come in 2, 5, 10, or 20 pounds.

Production

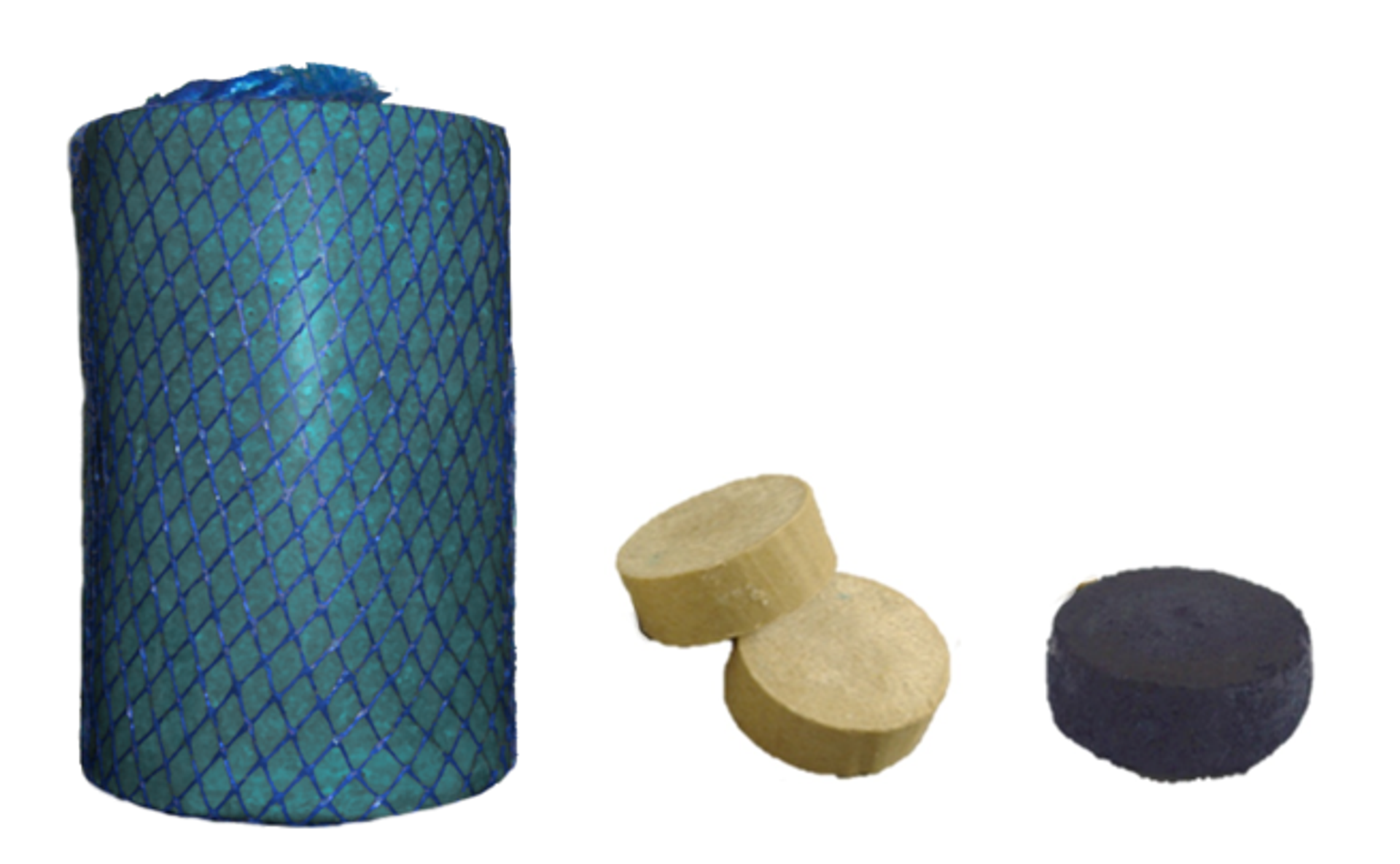

Many solids are created with a cast pour, while others are extruded (pictured right).

Because cast pours often lack the pressure necessary to compact the solid block, the density of solids can change from batch to batch. Not only is a solid that is not dense enough lighter in weight, it is also more brittle. When a brittle solid is placed in flowing liquid, there is a greater tendency for pieces to break off and flow out, as well as for the blocks themselves to fall apart, both of which cause the block to dissolve faster.

The extrusion process, however, ensures solid products are tightly packed in, which makes the block very solid. The dense nature of the product ensures that it dissolves uniformly over time, without breaking into chunks. The length of an extruded solid can also be adjusted to ensure that each block is the desired weight.

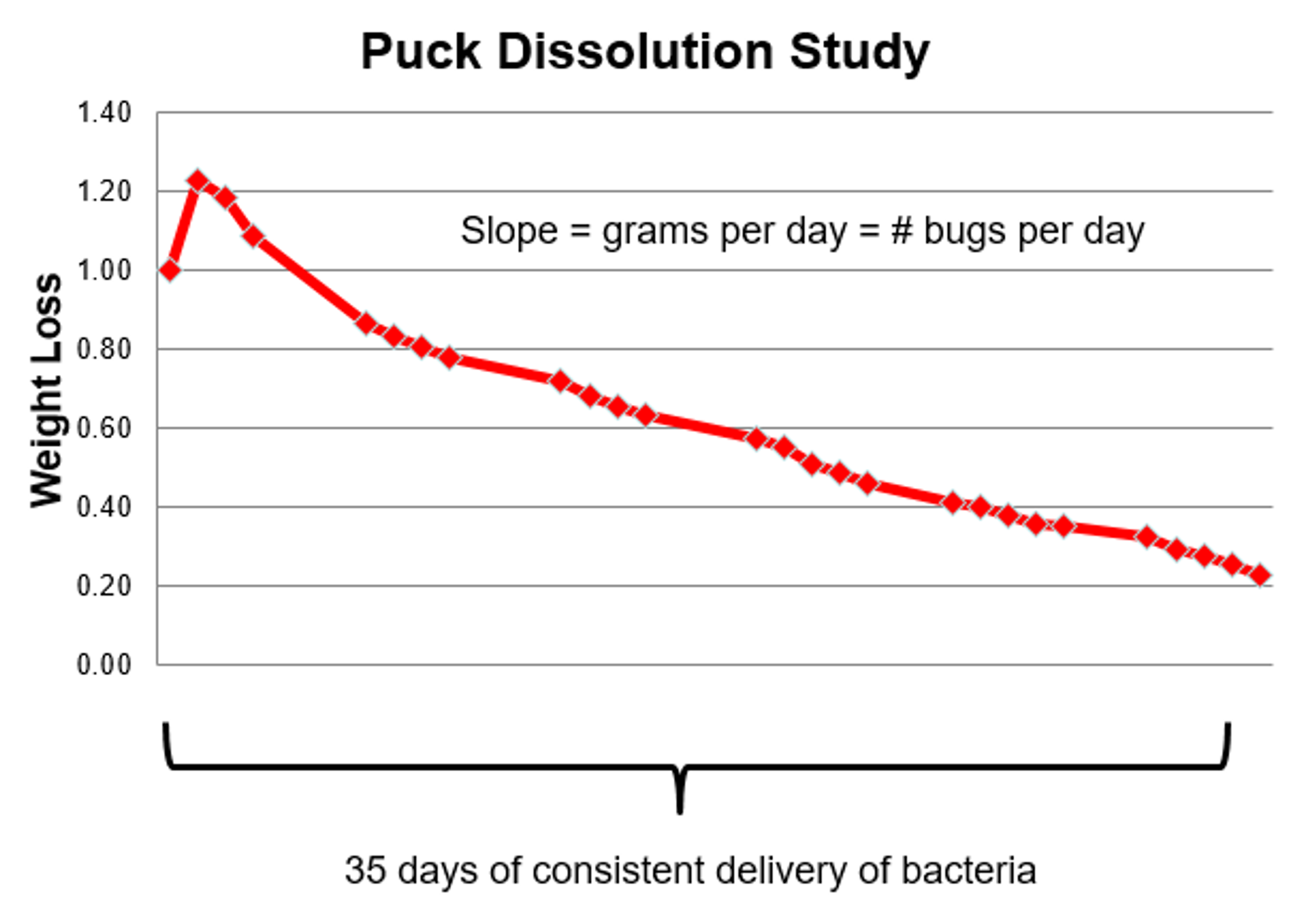

Puck Dissolution Study

We tested the dissolution of a 5-pound extruded EnviroZyme solid that was designed to last for 30 days in 60° F water, and the results of the study are reflected in the graph above.

The notable features of the curve include the relatively flat, linear decrease from days 4–39, and the fact that the initial weight gain only lasted for 4 days. Not only did this product dissolve to deliver bacteria at a consistent rate for 30 days, it lasted even for an extra 5 days. 5 billion bacteria per gram and over 11 trillion per 5-pound block over 35 days of consistent dosing delivers an average of over 320 billion bacteria per day.

While all EnviroZyme products in any configuration enjoy outstanding reputations based on the premises of first-time quality and on-time delivery, our next-generation extruded solids lead the industry in accurate and consistent dissolution, steady delivery of bacteria, and resultant effectiveness.

EnviroZyme can help you choose the best solid for your substrate, application, flow rate, temperature, and more. To get started please fill out the form below.