Aarhus Vand’s municipal wastewater treatment plant (WWTP) in Egaa, Denmark, equipped with an anaerobic sludge digester, significantly improved biogas yield and overall energy balance, while reducing sludge disposal costs through the use of BioVentris®.

Aarhus Vand is a Danish company treating water and wastewater for a population of 450,000 in Aarhus, the second biggest city of Denmark.

At the Egaa plant, which treats wastewater for a population of 100,000 people, the company was looking to improve anaerobic digester performance. They also wanted to improve energy balance by converting more organics into biogas, while reducing the solids volume of the sludge byproduct.

BioVentris was identified as a viable solution to enhance digester performance. BioVentris is an innovative blend of fast-acting enzymes that have been carefully chosen for their ability to hydrolyze and enhance digestion of fibers and proteins.

As more biodegradable (or organic) solids are degraded in the anaerobic treatment stage, more biogas can be produced with less solids sent to the dewatering system.

Product dosing was calculated based on the total volatile solids (VS) volumes of the combined sludge coming from primary filtration and secondary clarifiers, and initial Waste Activated Sludge (WAS). Dosing was set at 0.6 kg BioVentris per metric ton of volatile solids. Initial Waste Activated Sludge (WAS), with a setpoint of approximately 0.6 kg BioVentris per metric ton VS. The optimal dosing point was determined to be the recirculation system on the anaerobic digester. e Fig. 2. for a detailed flow diagram.

Upon initiating the addition of BioVentris, results started to show after a short ramp-up period. Comparing the enzyme trial period with the reference period, average daily methane production increased 12% from 1,737 m3 (61,000 ft3) CH4 to 1,941 m3 (68,500 ft3) CH4.

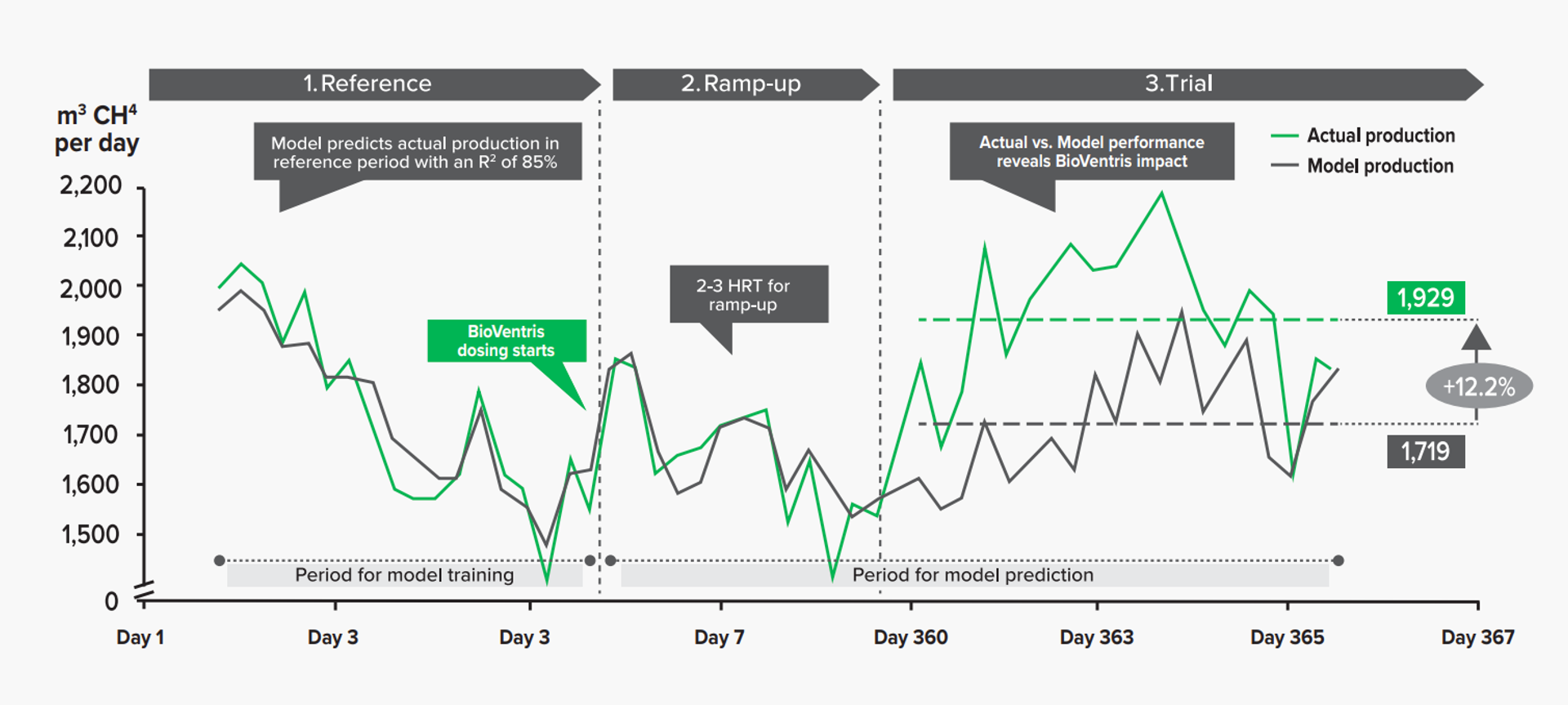

To further investigate the impact of BioVentris on methane production, data scientists developed a predictive model based on a range of important process variables (or features) including: sludge input to the digester, VS/TS ratio and primary/secondary sludge ratios.

As seen in Fig. 4., the model was able to predict actual production of biomethane with coefficient of determination R2 of 85% in the reference period. This value indicates that the chosen features were able to represent the variation in methane production well. Using this model to forecast methane production in the trial period, without BioVentris addition, showed a +12.5% gap between the model and the actual biomethane production, as a solid indicator of BioVentris performance.

The model applied to the observed data is called an Artificial Neural Network (ANN). To explain daily methane production, 23 process parameters were selected as model features (e.g., water flows, TS, VS, temperature, ammonia NH4 , Chemical Oxygen Demand [COD], alkalinity, etc.). The model is trained on data from the reference period [1], and predicts methane production for the Ramp-up [2] and Trial [3] periods. The R2 for the reference period is 85%, indicating a high model fit. Model predictions represent estimated methane production without addition of BioVentris.

A reduction in volatile solids exiting the digester was observed. Other potential benefits for Aarhus Vand were reduced polymer consumption and better dewatering performance resulting from improvements in sludge quality (lower VS%).

Through the use of BioVentris, Aarhus Vand was able to obtain a significant positive ROI in year 1 while improving the energy balance by 12%.

BioVentris enabled Aarhus Vand’s WWTP in Egaa, Denmark, to improve waste-to-energy conversion through increased biogas production, reducing sludge and overall plant CO2 footprint.

The BioVentris solution helped the plant economically, while making a positive impact on the environment.