BioSpikes® 5000 Reduces Pulp Mill Sludge and Increases Lagoon Capacity

A Canadian pulp mill was able to reduce sludge and increase lagoon capacity by 2000 m3 (54,000 ft.3) with BioSpikes® 5000.

Benefits

- Reduction of sludge in some areas of 1.5 m (4.9 ft.)

- Average sludge reduction across treated area was 0.75 m (2.4 ft)

- Increase in aqueous phase of 2000 m3 (54,000 ft3)

- Improvement of effluent quality

Background

For decades, a Canadian pulp mill has been accumulating solids in its aerated wastewater lagoon. This buildup reduced the capacity and retention time in the lagoon and began affecting effluent quality. Technical assessment of the lagoon revealed that it had as little as 0.5 m (1.6 ft.) of freeboard on a 4 m (13 ft.) depth at one end, corresponding to 3.5 m (11.4 ft.) of accumulated sludge. To degrade and compact the sludge, increase treatment capacity and further delay the need to dredge the entire lagoon, the use of BioSpikes was proposed.

Application

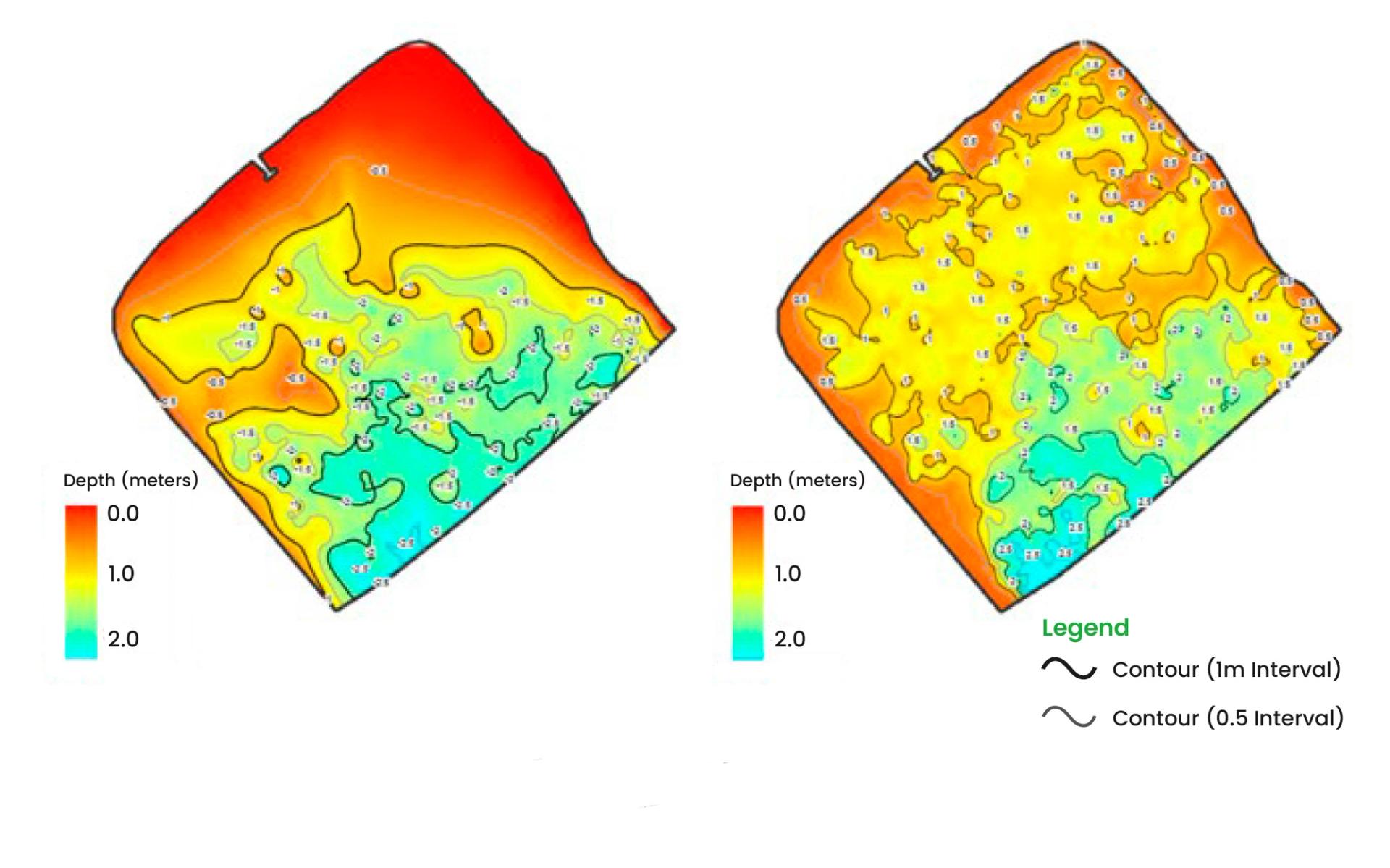

Fifty cases of BioSpikes 5000 were applied over a 5-acre zone. The spikes were applied periodically between April and July. A local engineering company performed a bathymetric (underwater topography) survey prior to bioaugmentation, and returned to the plant for re-measuring after treatment with BioSpikes 5000.

Results

An increase in lagoon capacity of nearly 2000 m3 (54,000 ft.3) was recorded. Several areas showed a sludge reduction of more than 1 m (3.2 ft.) while average reduction across the lagoon area amounted to 0.75 m (2.4 ft.).

| Basin Capacity | |

|---|---|

| April | 26,154 m3 |

| October | 28,125 m3 |

Note:

1. Basin capacity table: The volume of water present between the sediment/water interface and surface water elevation on the date of sampling. Basin capacities are presented for the surveyed portion of the pond only.

2. Surface water elevation was 38.30 cm below the reference elevation benchmark in mid-October. Surface water elevation was not surveyed during the April site visit.

Conclusion

Treatment of the pulp mill's lagoon system with BioSpikes 5000 to the pulp mill’s lagoon system successfully increased capacity and retention time, which improved effluent quality. This delayed a potential dredging project, which would have cost several million dollars.