Loading…

The cold weather is about to arrive in most of areas and as a result, winterization of wastewater treatment operations is underway to accommodate the harsh weather. The drop in operating temperature of wastewater systems can have a significant impact on plant operation and effluent quality.

The most apparent effects can include icing of equipment, ice formation on water surfaces, particularly on lagoons, freezing pipes, and power outages. However, preparing for these physical impacts is not the only area where plant operators need to anticipate the winter weather.

Temperature drops, like most chemical reactions, also impact the biochemical reactions associated with bacterial metabolism and reproduction. Reactions rates typically decrease by a half for each 10° C drop in temperature. This drop in reaction rate can be translated as a drop in activity. Temperature changes can also alter the microbial ecology of the biomass, selecting psychrophilic and psychrotolerant bacteria as well as altering enzyme pathways. This change over in populations is not insignificant and can take multiple sludge ages (months) to occur. If operations are not modified to account for the decrease in biological activity, the plant operators can experience poor BOD reduction.

"Reaction rates typically decrease by a half for each 10° C drop in temperature."

The most common operational change made to winterize a treatment system is to elevate the concentration of biomass by 25-50%. Because bacteria are working at a slower rate, and hydraulic retention times are the same, more bacteria are needed to maintain similar oxygen uptake rate (OUR) activity and BOD removal. Winterization should be planned for during the fall, as operators will find difficulty in raising biomass concentrations after the cold weather has arrived.

"… to winterize a treatment system, the most common response is to elevate the concentration of biomass by 25-50%.”

This operational change has some drawbacks as carrying a higher biomass increases oxygen demand, decreases oxygen transfer efficiencies, and promotes low F/M filamentous bacteria, in particular Type 0041 and Type 0675. The increase on oxygen demand is often offset by the increase of dissolved oxygen solubility in colder water. The use of BioRemove COD LT is one of the simplest ways to quickly shift the microbial ecology to prepare for winter. This product has been formulated using cultures that can not only survive, but thrive at temperatures as low as 5° C.

Industrial treatment plants typically have to increase nutrients during colder temps to compensate for not only the increase in biomass but the increased requirement for cell maintenance. Some industrial facilities may have the ability to adjust the temperature of their wastewater by bypassing retention basin or allowing water cooling system to perform less efficiently in the winter. Depending on the system design, the loss of equalization could subject the wastewater system to more severe spill and slug loading issues.

Upsets occurring in cold weather systems can often take 2-3 times longer to recover from than during high-activity warm systems. In systems, with high FOG loadings, the filamentous bacteria Microthrix Parvicella can cause severe foaming and sludge bulking as the drop in temperature impacts the solubility of fats and long-chain fatty acids. The less soluble the fats are, the more these hydrophobic bacteria can consume them at the water-air interface.

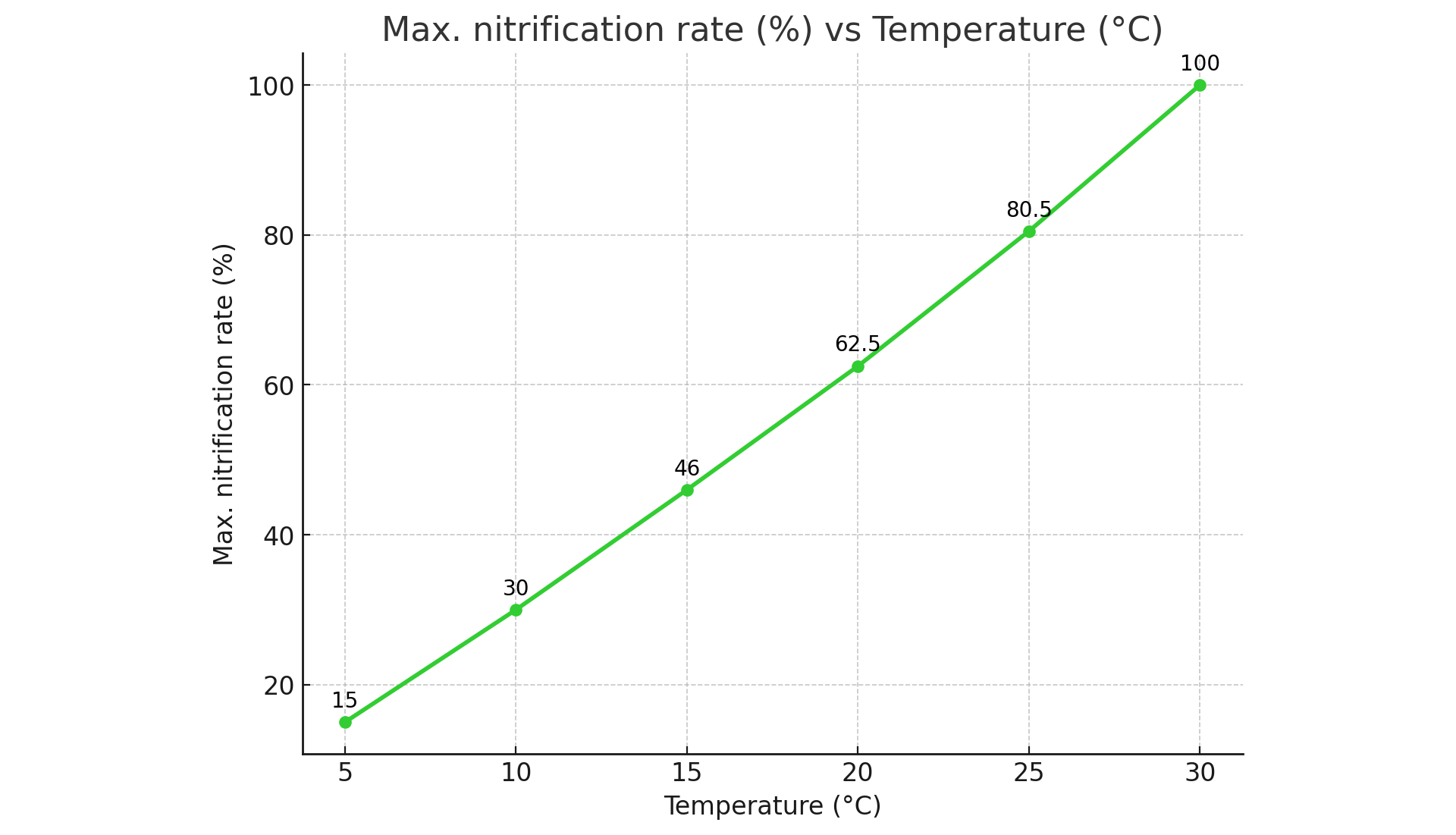

The most recognizable impact of cold weather on system is the loss of nitrification. Nitrifying bacteria are generally some of the most sensitive bacteria in a wastewater system and are often the “canary in the coalmine” that indicates a fundamental population shift. Nitrifying bacteria have some cold tolerance to their survivability, however, to avoid loss of nitrification, systems should typically not drop below 10° C.

“Typically, systems should not drop below 10° C to avoid loss of nitrification.”

Activated sludge systems do not often drop below this threshold, but aerated ponds and lagoons quite often do. One of the benefits to increasing the biomass concentration during winterization is that it can help retain nitrifiers. Aerated ponds that require nitrification during the winter often require nitrifier bioaugmentation and can benefit from the addition of a fixed media to retain them. Our BioRemove AM is the highest quality commercially available nitrifier and has proven efficacy down to at least 8° C.

As more plants begin to use denitrification strategies to meet stricter total nitrogen limits, the tolerance of denitrifying bacteria has come under more scrutiny. Similar to nitrification, systems that maintain operating temperatures at or below 10° C often experience poor denitrification. Poor denitrification can be exacerbated by maintaining high biomass concentrations where carbon demand is high.

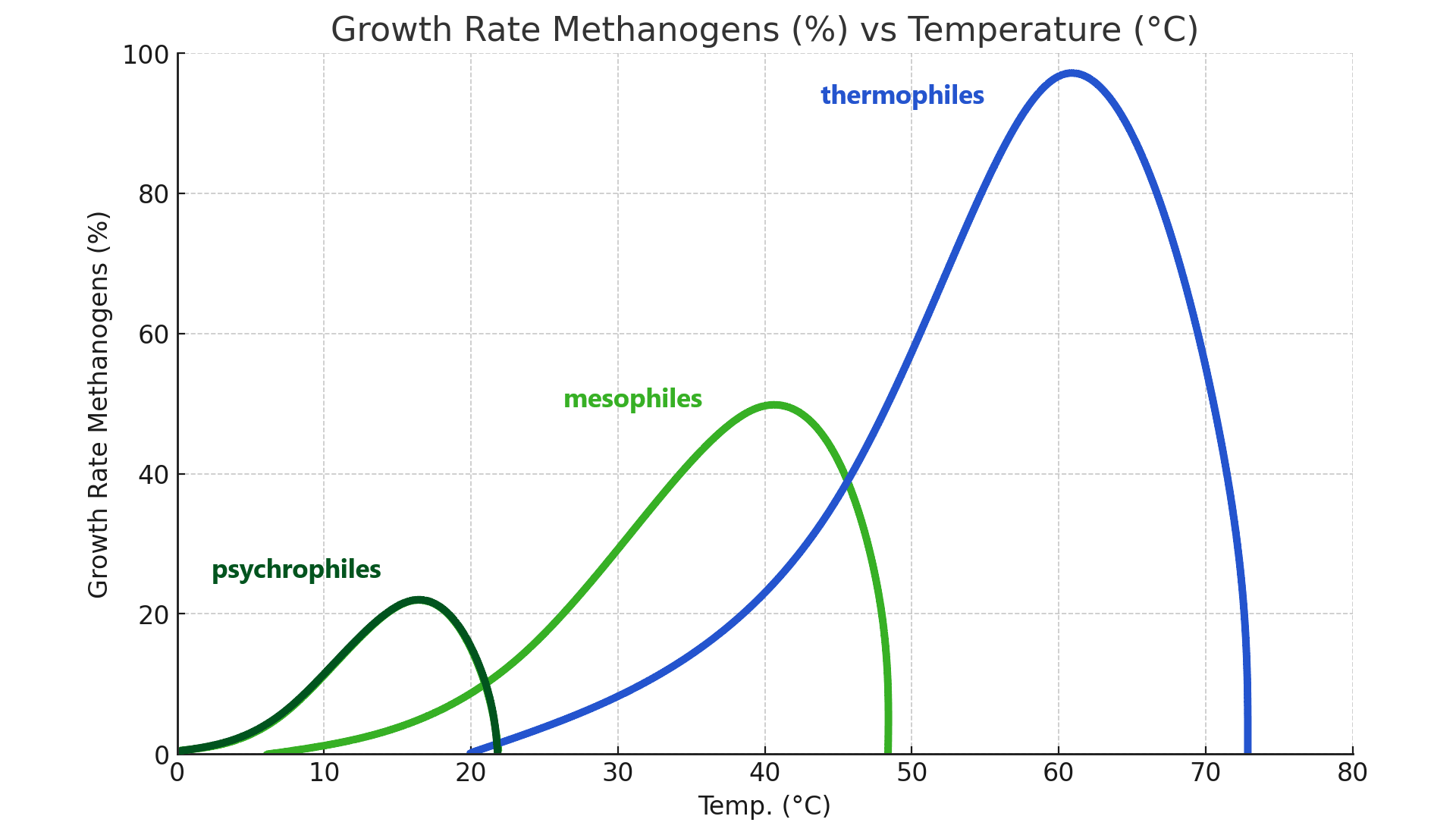

For industrial sites using anaerobic pretreatment, winter is often the costliest month to run their digesters due to cost to maintain mesophilic temperatures and/or the drop in efficiency related to lower biological activity. The drop in anaerobic bacteria activity can often lead to lost biogas production and increased downstream treatment costs. BG Max 3000 has been trialed in a handful of industrial facilities during the winter seasons which were subject to significant drops in digester temperatures. Augmenting the system with BG Max 3000 increased biogas production to levels that exceeded the average biogas produced during typical warm weather.

Operators should also evaluate their system for any areas where they are using heat and develop an insulation strategy. Anaerobic systems which receive slowly degradable material may also see accumulation of floating layers due to reduced metabolic rates. BG Max 3000's enzyme portfolio can help keep hydrolysis going and prevent accumulation of solids.

When possible, maintaining the temperature within the treatment system may be assisted by the following:

In addition to the physical options above, the biomass can be supplemented to resist the effects of the cold temperature. EnviroZyme can assist by providing the following bioaugmentation solutions:

Winter weather brings operational challenges to plant operators but with a sound operational strategy aided by bioaugmentation solutions from EnviroZyme, plant operators can overcome even the toughest winter season challenges.